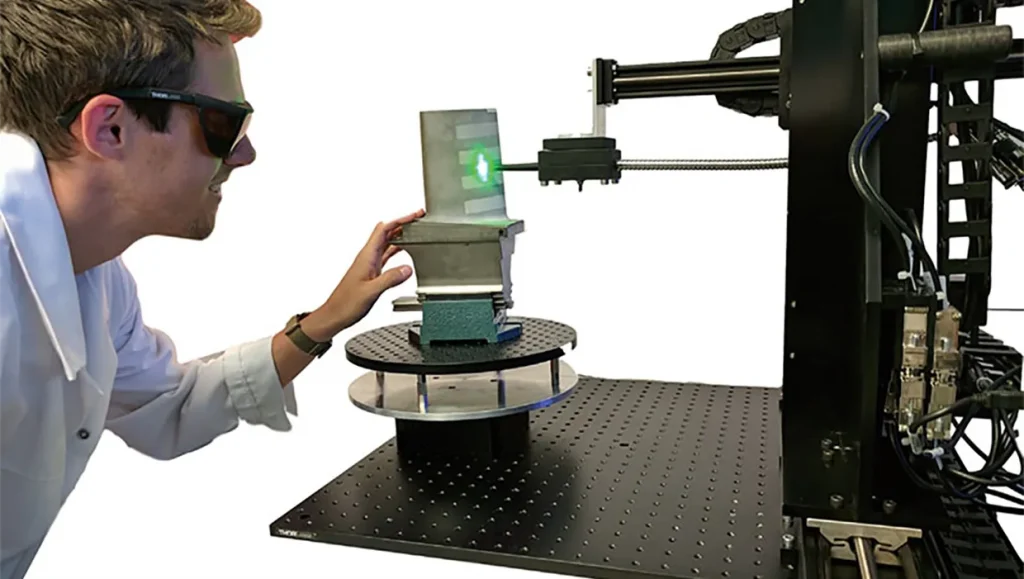

Sensor Coating Systems (SCS) specified a positioning system for the rapid scanning of gas turbine and automotive components. The system enables accurate thermal mapping of hot components post-operation. The patented technology uses a combination of temperature memory materials, specialised instrumentation and automation.

SCS, which has worked with us over a number of years, commissioned this latest project to design a positioning system to improve the reliability and consistency of their scanning and measurements and we customised a positioning system to enable the rapid scanning of the components using their laser induced luminescence technology.

The requirement

A customised XYZR Positioning system was required to scan an area of 500 mm x 500 mm x 500 mm and move a fibre optic measurement probe over the volume at speeds of up to 20 mm per second. The equipment was to be designed and manufactured as a “stand alone” piece of equipment which would then be mounted at SCS onto an optical work surface.

A key requirement of the project was to achieve uniformity of scans and positional repeatability was very important.

The solution

The XYZR motorised scanning system consists of tried and tested linear dovetail slides and a worm and wheel driven rotary table, each axis being driven by a stepper motor.

The system is manufactured from a high-grade aluminium alloy and employs linear dovetail bearings with precision leadscrews for accuracy and reliability.

The system enables the automatic acquisition of 300 measurement points on a complex turbine blade in 2.5 hours.

About Sensor Coating Systems

Sensor Coating Systems Ltd spun out of Southside Thermal Sciences, itself an Imperial College spin out, in 2012. SCS pioneers sensor technology based on luminescence materials for engineering applications in demanding environments. Its award-winning technology enables accurate temperature mapping and, in doing so, assists in optimising the operation of machinery, lowering fuel costs and maintaining material integrity.

The main industrial sectors for application are the power generation industry, aero engines, automotive and machinery operating in extreme environments such as oil & gas and petrochemical plants.

SCS is internationally orientated and works with companies such as MAN Diesel & Turbo, Alstom (now GE) and Snecma under collaborative agreements and also with reputed institutions such as EPRI and the German Aerospace Centre.

Features of the XYZR System

| Usable travel | 500 mm x 500 mm x 500 mm |

| Positioning repeatability | XYZ <0.05 mm, uni-directional R <0.01 degree, uni-directional |

| Working speed | XYZ, up to 20 mm per second R up to 90 degrees per second |

| Working load | XYZ, up to 1 kg R, up to 50 kg |

| Limit switches | Microswitch fitted at extremes of travel |

If you are looking for a dedicated partner to work alongside for your electro-mechanical motion project, get in touch.

We’ll work with you to develop the best solution for your specific challenge, no matter how complicated.

Arrange a visit and meet the team: