Just like encoders and motors have had to advance to meet the demands for higher throughput and smaller products, so have the interfaces they use to communicate. Automating production ultimately depends on the fast and accurate transfer of data. The intensely competitive race to digitise and gather actionable data has put added emphasis on what an interface can handle.

What is an encoder interface?

HEIDENHAIN’s EnDat is an example of these interfaces, a digital, bidirectional connection between the encoder and the subsequent electronics. Along with position values, EnDat can now transmit data for a variety of uses, including evaluation of an encoder’s function reserve through online diagnostics.

Encoder interfaces suited for Industry 4.0

Looking back at the evolution of the interface, we can see how it has adapted to the times of Big Data and Smart Manufacturing. HEIDENHAIN’s first introduced EnDat in 1995 with, EnDat 2.1. It was a combination serial/analogue signal with basic alarms, warnings and easy integration. The next generation, EnDat 2.2, was introduced in 2003 and marked the transition to purely serial data transmission. EnDat 2.2 also added a whole new layer of capabilities, transmitting actionable information on things like temperature sensors, functional safety and online diagnostics without sending a separate request signal.

A future-ready interface

The recently released EnDat introduced even more data-based features and transmission capability. It is a direct answer to the data, speed and accuracy demands of today’s world. Before we look at all the different ways interfaces work and how they add value, let’s look at some of their latest capabilities.

High data volume and speed

- Transmission of position values and sensor data

- Send lists permit predefined communication for various operating scenarios

- Up to 15 additional information slots per communication

- Access to the encoder memory during normal operation

- Extensive system monitoring for Industry 4.0

- Automatic system installation and diagnostics

- Sensor data

- Short cycle times

- 15 µs can be achieved with very low position-measurement jitter

- High bandwidth

- 5 Mbit/s at 100 m cable length, or 25 Mbit/s at 40 m

Advanced sensor compatibility and diagnostics

- Electronic ID label for automatic system installation

- Data for the encoder, motor, and system

- Online encoder diagnostics

- Together with further sensor data, forms the basis for condition monitoring and predictive maintenance

- Mobile access to diagnostics

- Storage of operating status data

- Storage via the subsequent electronics

- Data acquisition through the encoder

- Functional safety

- For safety-related applications up to SIL 3

- Black-channel communication

- Convenient implementation thanks to data separation for motion controller and safety controller

- For safety-related applications up to SIL 3

Encoder interface applications

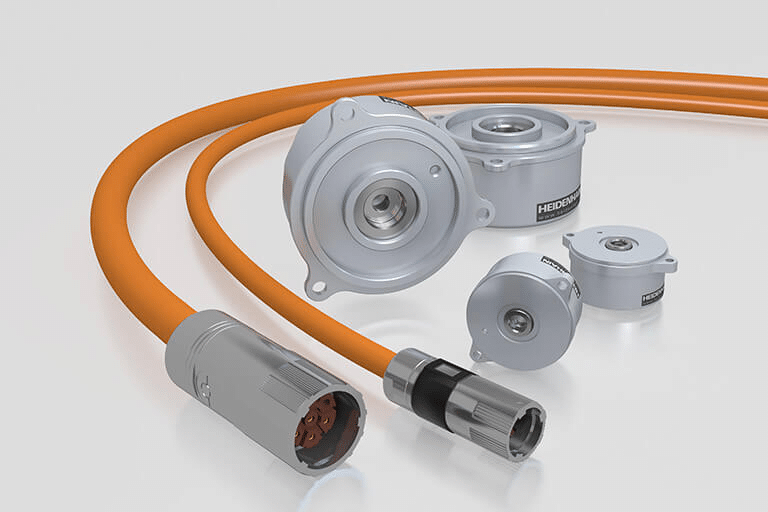

Encoder interfaces like EnDat can be used with almost any encoder type or drive system and even some measuring tools—including several from within the HEIDENHAIN Family of Brands. Serial interfaces have proven versatile and effective across industries, and as technology has advanced there are specific modern applications where they are especially adding value.

Hardware EnDat can work with

Interfaces like the HEIDENHAIN EnDat can work with different measuring and scanning methods, both linear and rotary, depending on the optimal encoder for the application. These interfaces are also compatible with other equipment.

- Absolute or incremental positioning encoders

- Photoelectric, inductive or magnetic scanning encoders

- Single turn encoders

- Multiturn encoders with gears

- Multiturn encoders with buffer battery backup

- Integrated encoder modules

- Touch probes

- Length gauges

- Cabling variety

- Hybrid cable technology

- Bus operation

- Integration of sensor boxes

- Additional sensors

- Sensors inside the encoder

- External sensors

Interface compatible equipment

A vast majority of major drive manufacturers globally have seen the benefit of EnDat and included the interface with their current and future offerings. Each year, more solutions and implementations come to the market supporting various functions of EnDat.

Automation interface applications

Automation and robotics depend heavily on the transmission of fast, accurate uninterrupted data from the machinery to a control or hub where data is saved or analysed. These capabilities make analysing and maintaining uptime a huge value add in automation environments:

- HMC 2 hybrid cable

- Bus operation

- Sensor integration (e.g., easy connection of a temperature sensor inside the servomotor, with characteristic curve selection for a KTY 84-130 or PT 1000)

- Acquisition and storage of operating status data

- System information for automatic configuration

- Enhanced diagnostic capabilities

- Functional safety

Machine tool interface applications

In the violent world of metalworking, interface hardware must be able to endure the vibration and contamination associated with tens of thousands of RPMs, coolant, chips, and heat and still send accurate signals—a millimetre can make the difference between a good part and scrap. Here are some of the interface characteristics to look for:

- Mechanically robust cabling

- Integration of complex sensors and sensor boxes

- Multi-dimensional measurement technology

- System information for automatic configuration

- Enhanced diagnostic capabilities

- Storage of operating status data

- Functional safety

Electronics industry interface applications

The level of accuracy and precision required in industries like front- and backend semiconductor work means everything from the weight of the wiring to high-resolution measurements must be in synch. Here are a few ways the right interface helps makes it possible:

- Weight reduction due to thinner cables and bus operation

- Multi-dimensional measurement technology

- System information for automatic configuration

- Enhanced diagnostic capabilities

- Storage of operating status data

Take a deeper dive into the evolution of interface electronics and the capabilities of systems like EnDat 3. From functional safety to advanced sensor transmission, the right interface unlocks to full force of Industry 4.0 in settings far and wide.

Contact us to take a deeper look into the evolution of interface electronics and the capabilities of systems like EnDat 3. From functional safety to advanced sensor transmission, the right interface unlocks to full force of Industry 4.0 in settings far and wide.