Precision Acoustics is a leading global supplier of products to measure ultrasound acoustic pressure and intensity. As part of its ongoing research and development programme, the company required a motion control system to use over a water tank for high and low-frequency ultrasonic measurement testing. In the tank, sound waves are projected at designated objects in the water, and the resulting wave echo measured to an incredibly accurate standard.

The challenge

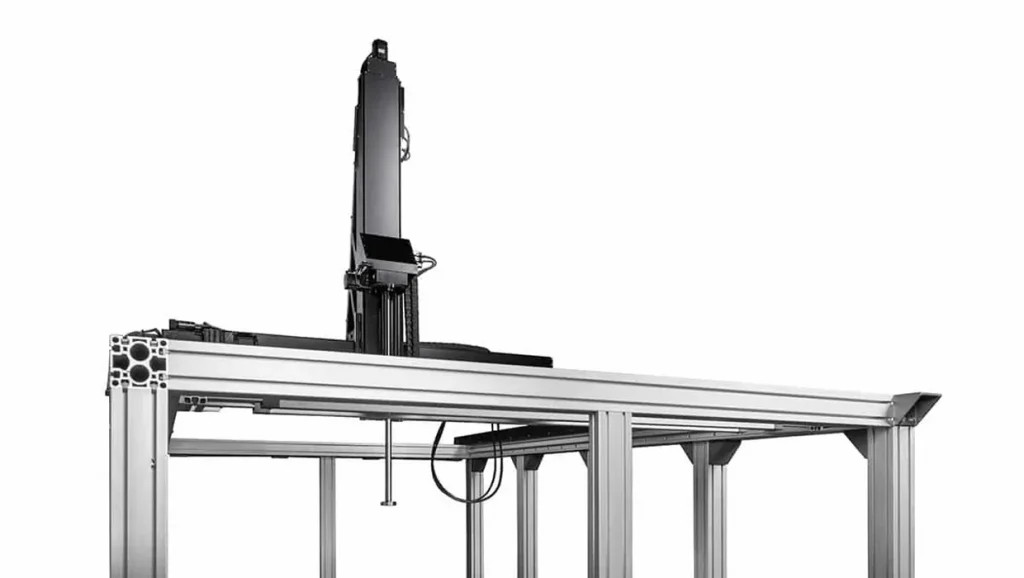

The water tank, which is 3 m x 1.5 m x 1.5 m and filled with UV filtered water, created a number of challenges for the motion control unit, which needed to operate a total of 9 axes across two scanning volumes of up to 1.5 m x 1 m x 1 m with 360º rotation around a vertical axis.

Firstly, we had to address the measurement requirements. With a probe attached to the motion control unit in the water, the system needs a linear resolution of less than 0.01 mm, with an angular resolution of better than 0.01º.

This wet environment also demanded that any solution must be corrosion resistance and provide exceptionally smooth motion to cater for the frequency ranges being measured. To ensure the motion system did not interfere with measurements, a rigid framework was created to sit around the water tank to isolate the mechanical system and avoid potential disturbances to the tests.

The solution

The electro-mechanical system is guided with SCHNEEBERGER linear bearings coated with Duralloy® for protection from the water and driven with precision ball screws by the TITAN range of motor drive control units on each of the linear slides. The rotation units are based on the LGR2090 rotary table to provide stability and a gimbal unit was designed specifically to meet the needs of the ultrasound research scientists.

Attached to a rigid aluminium frame, from MiniTec UK, the system fits around and over the water tank to accommodate the water treatment system and control cabinet.

If you are looking for a dedicated partner to work alongside for your electro-mechanical motion project, get in touch.

We’ll work with you to develop the best solution for your specific challenge, no matter how complicated.

Arrange a visit and meet the team: